Powerfeed Unit Adjustment

What follows aims spindle moulder but power feeder adjustment remains nearly the same whatever the operation we want to work with. The feed direction switch enables forward or reverse feeding and the swing ability allows the workpiece to be slightly pinched against the fence. Then height adjustment keeps the workpiece against the table.

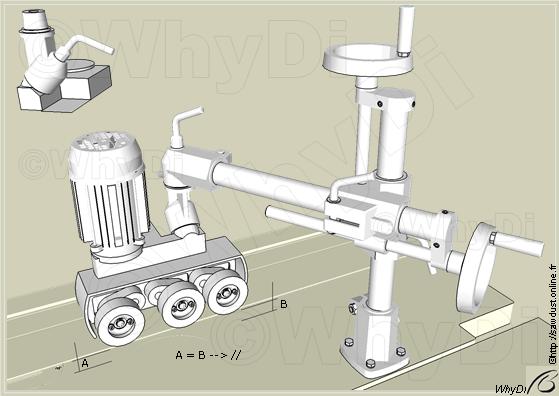

Founded on my own experiment, tuning up the pivot axis of the motor square to the table makes easy all further adjustments and only requires a straight stock of wood and a tape or may be achieved without measurement using a spirit level.

The same way, spending some minutes to tune up parallelism between wheels and table enables much time to be saved when setting. By the way note that parallelism depends upon previous square adjustment. The first one directly drives the second.

From there we just have to rotate the feeder around its vertical column and adjust the horizontal arm so that the working tool axis divide the gap between the two first wheels by about two.

Then setting the parallelism so that the wheels tend to slightly pinch the workpiece against the fence which means the outfeed wheel locates about five millimetres closer to the fence plate than the infeed wheel.

The quickest way I have found to adjust the height is to lower the feeder wheels watching they get nearly flush to the workpiece top then rotate the handle another turn and a half. A full rotation of the crank equals 2.5 mm (a tenth of an inch).

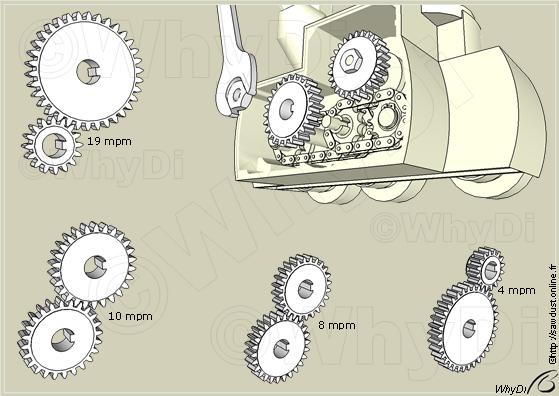

Lastly replacing two sets of two gears that can be inverted from the top to the bottom shaft changes the feed speed which means four feed rates : 4, 8, 10 and 19 meters per minute (13, 26, 33 and 62 feet per minute).