Riving Knives Two Positions

Preamble : I don't want to write another list of what each woodworker should know in order to work safely. Everybody may find what matters using a search engine with key words "woodworking safety". Albeit all these articles talk to the others and I would have liked to find someone writing : "for my own safety I try to..." which means many more people convey a standard point of view about safety without wondering anything. I avoid these kind of topic that lead to nothing most of time. On the other hand I get involved in every exchange that tend to explain why something would be unsafe et try to find out a better way. It's all about mental attitude and the last one requires the point of view to be argued. Nothing good nothing bad but keeping open minded.WhyDi

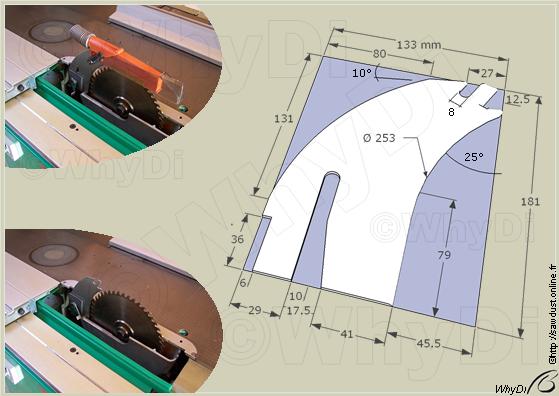

The two-position riving knives were made the same way my former ones. I reused the one matching 300 mm blades in diameter and cut a new 250. In order to simplify I gave up the 280 which became a template and the matching blade. Holding the overhead saw guard they needed a high position to come up above the top blade and a lower one enabling non through cuts such as dadoes and rabbets or else scoring cuts. The riving knife holder needed some modifications so that quickly switching from the low to the high location without any tool and adjustment.

Here is the knife matching the 300 mm blade in diameter. It rotates at a ten degrees angle from the same axis that the blade to go from the high to the low locations. Whatever the position the knife sits on the stop gauge and revolves around that point in the direction of the blade. The correct lock position is reached as soon as the knife groove leans to the guide of the rear flange. After clamping the knife can not go closer to the blade teeth. That way I don't need to adjust the placement and due to the nut lever no tool is required.

The 250 mm works the same and the one knife matching one diameter choice I made for long allows the switching between 250 and 300 without adjustment. The top groove at a twenty five degrees angle accommodates the over blade guard and because of the design of the guard nozzle the groove position was an issue as regard the 250 riving knife.

There is always a price to pay when reusing an existing accessory. Here it is. The typical and efficient dusthood shape of the overhead guard strongly impacted the knife top. I tried to build my own but the origin one captured the dust so effectively that the reasonable choice was to not replace that part. As a consequence the riving knife front was curtailed. It slightly affected the 300 one that just left some millimetres but the 250 shortened by more than twenty millimetres in length and fifteen in height. Related to the circumstances it could be unacceptable and I choose to keep the former one. It takes no room and may turn out useful.