Making Loose Tongues on the Spindle Moulder

Loose tongues merely replace tongue and groove joint and although many people make their loose tongue with the help of the planer-thicknesser I always go for the spindle moulder and a dedicated jig mostly because of my need of 2.5mm or 5mm thickness. I occasionally machine a some dozens of tongues from hardwood left in the shop and store them near the workbench as you may see below.

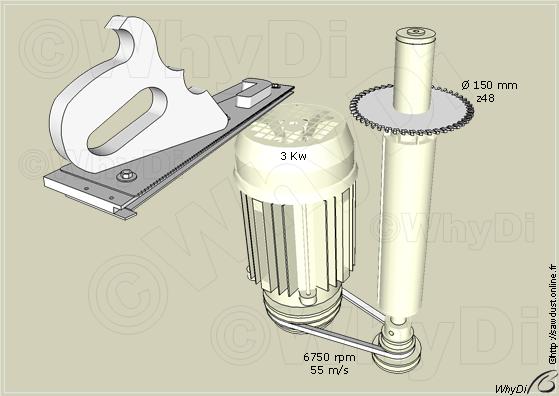

The jig is detailed at the bottom and I usually lock a fine saw blade on the spindle moulder shaft. Typically such blade does not purpose cutting with the grain but despite a bit more drag force the two faces of the loose tongue come out ready to use.

After sanding square or else simply squaring on the table saw, the workpieces go through the blade along the continuity plate then I rotate the board once upside down before a second pass and turn the wood horizontally for the following cut, again and agin until the jig could not pinch the wood against the fence.

Here are the details of the jig. An old back saw was taken in pieces then reassembled such way the teeth tend to push the workpiece against the fence. The L shaped stop accommodate the forefinger and the thumb of the left hand whereas the right hand on the wooden handle push the work.